Shrinkage: Don’t Get Fleeced On Your Next Bag Project!

Lazies, Does your fusible fleece shrink? Not sure – go test it. It could be affecting your projects. Some of the fleece products on the market today do shrink. When making a bag, you might have wondered why your project looks a little wonky when you cut everything perfectly. Or the bag lining seems really big, but it was cut the same size. In a word: shrinkage.

I recently ran out of my beloved Dreamy Fusible Fleece. The mill I work with decided not to make it any more. That started a search for a new mill and testing prototypes. One prototype in particular shrank when exposed to heat. No thank you, I’ll try elsewhere. Meanwhile, let me show you what I’m talking about.

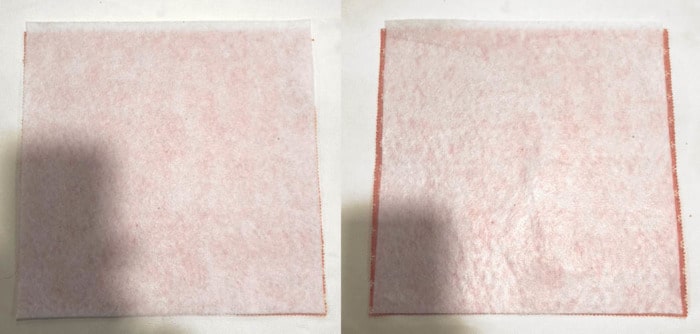

Prototype Fusible Fleece: Before and After

(Pardon the partial eclipse of my phone.)

Note: Fusible fleece shown in this example. The results were the same for the sew-in fleece.

Left image: The fleece and pre-shrunk fabric are 10″ wide, you can see that they match at the side and bottom edges.

Right Image: When fused according to directions, the fleece shrank in from the side edges of the fabric. There was little shrinkage at the bottom edge.

But Wait…

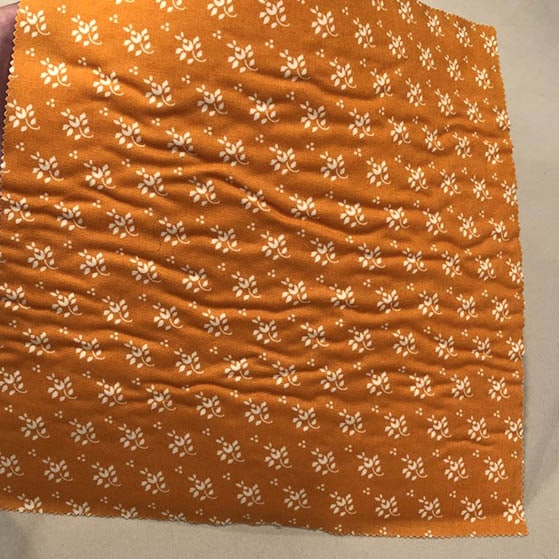

And if shrinkage isn’t bad enough, fleece shrinking could also cause wrinkles, which I now call shrinkles (shrinkage + wrinkles).

These shrinkles happened because the fleece shrank and the fabric didn’t. Also, notice all the wrinkles are in one direction. The fleece shrank in one direction, either across the bolt from selvage to selvage, or lengthwise. Doesn’t matter which.

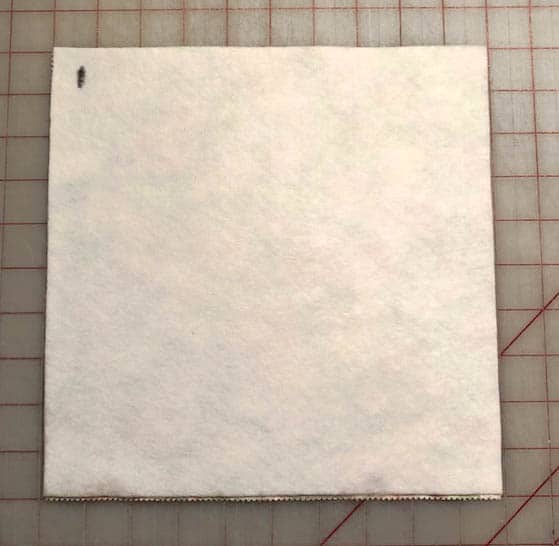

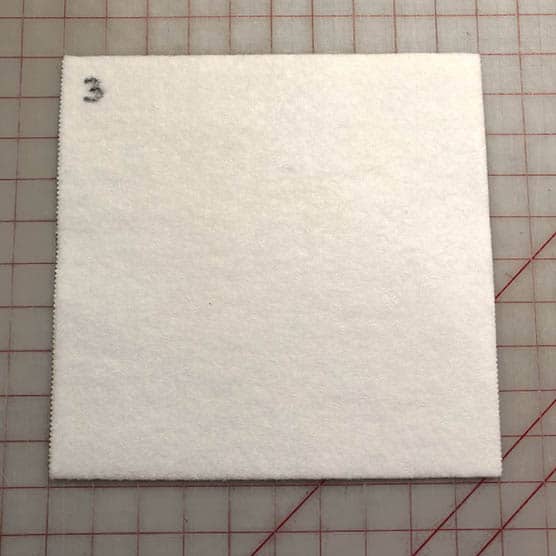

Prototype Fleece

Next, I tested the fleece prototype by itself to rule out the fabric as the issue. I hovered a hot iron over the fleece and used the steam button. My goal was to expose the fleece to the amount of heat and steam it would encounter while constructing a bag. Guess what – it shrank about 5%. The mill said the product relies on adhesion to fabric to stabilize and prevent shrinkage, otherwise it is expected to shrink 5-7%. Wow! That doesn’t wash with me.

That edge is creeping up (literally) close to 1/2″.

Bizzarro Land

This is just plain odd. In the image above, the edge shrank more than the corners. I’m not sure what’s at play here. I tried to use even exposure to the elements. That little bowing along the edge showed up when fused to fabric, too.

NOTE: Rest assured – I am not using that prototype product for my Dreamy Fleece, sew-in or fusible. I’ll be out of stock until I can find a mill that can reliably make a product I like. That means it could be a while and I’m sorry about that.

Reality Check – The Other Guys

I’ve used fleece from many manufacturers and most have some shrinkage. The worst offenders have approximately 5% shrinkage. Most are no more than 1-2% shrinkage, which I find acceptable. Some have no perceptible shrinkage.

After the scary incident with this prototype, I went to my years-old fleece stash and tested all the brands I had on hand. Note – these are old samples and may not represent what’s currently available. I don’t know. I’ve been working with my own fleece and haven’t bought anything new in years.

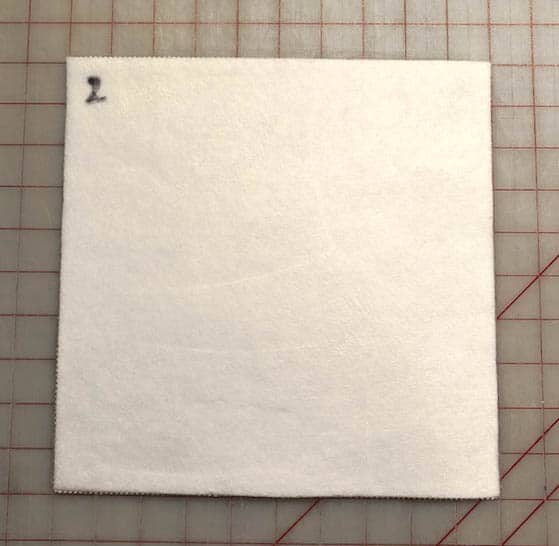

Shrinkage can happen across the width, or along the length, or both. I cut 10in squares of fabric and fleece. Fuse, then re-measure. It’s not scientific, it’s logical. To rule out fabric shrinkage, pre-shrink (or wash) the fabric.

Above: Marginal shrinkage. Not quite 1/8″ over 10″.

Fleece pulled away from the fabric at the bottom edge.

Above: No perceptible shrinkage.

Above: Shrinkage of just more than 1/8″.

Fabric and fleece shrank at the bottom edge.

The Other Side Of The Coin

The fleece in the image above also created a cellulite appearance on the fabric side. The fleece has an uneven surface with a lot of adhesive. The adhesive sucks the fabric down into the fleece for instant cellulite. Our projects deserve better.

All three of these samples have an acceptable amount of shrinkage in my opinion.

I know you are wondering which brands I tested. It doesn’t matter. Products change over time. It’s simply best to test. Find one you like and know how it behaves.

Curious: Top vs. Bottom

One thing I discovered while testing all of this is that shrinkage can vary based on how you fuse: fleece on top vs. fleece on bottom.

I had slightly more shrinkage when fusing with the fleece on top, with the fabric face down on the pressing surface.

How Does Shrinkage Affect Our Projects

- For easy math, let’s work with a bag project 20″ wide x 10″ tall.

- Shrinkage of 5% is 1″ across the width and 1/2″ top to bottom. That’s substantial!

- A smaller amount of shrinkage at 2% is about 3/8″ across the bag and only 1/5″ top to bottom.

- Using one fusible on the outside of the bag, and another on the lining could be the culprit behind a baggy lining, seeming to be too big for the bag.

What To Do

Whenever you buy an interfacing, test it before using it in your project. Some brands work with the same mill from batch to batch and offer a consistent product. Some don’t. If the product looks different than the last time you bought it – it probably is. Test it again.

How To Test

- Cut a 2″ x 10″ piece off the selvage edge and another off the cut edge. Pre-shrink the fabric. Then fuse the two test samples to the fabric and re-measure.

- Press your project fabric really well before beginning and think of that as pre-shrinking.

- You can always work with larger pieces of fabric and fleece, fuse them together, then cut the pieces you need.

- For linings, consider doing a little ‘tailoring’ by increasing the side seam allowances. And you can trim the height down a smidge, too.

Dreamy Fusible and Sew-In Fleece

My fleece is wonderful. It has a dreamy, cloudy feel, with a smooth surface and the right amount of adhesive to get the job done. It’s the best of all worlds. I will continue to look for a new mill.

NOTE: Rest assured – I am not using the prototype product shown in this post for my Dreamy Fleece, sew-in or fusible. I’ll be out of stock until I can find a mill that can reliably make a product I like. That means it could be a while and I’m sorry about that. We do have some packaged cuts of sew-in and fusible Dreamy left. Contact me if interested.

Subscribe to receive emails for my blog and newsletters about new patterns and project ideas.

Enjoy!

Joan

Joan’s Sewing Group | Pinterest | Instagram | Twitter

Like and share this post with your stitchy friends.

So, what was the advantage of keeping the product names of the fleece you tested , a secret? I know your search must be frustrating and exhausting, but you want all your readers to go through the same thing? Not nice!

Hi Donna, The product I tested is old and may not be the same that’s available today, but it all had acceptable shrinkage for me. The important point is to test the product you like so you really know what you are working with.

Can’t fleece, just like fusible interfacing be pre-shrunk in hot water?

It adds time to a project, but may render your stash salvageable if you find this is a problem.

Thank you for this article. Who would have guessed the great amount of shrinkage. It looks like plan B is to cut larger, quilt the pre-shrunk material and fleece together and then cut to proper size. Have a project not yet started, will do that. Thank you, Sloane

Where is your Dreamy Fleece sold? Quilt shops only, your site only? I finally found the Stiff Stuff at my local quilt shop.

Oh my gosh! I have never used your products because I haven’t seen them in Canada, I thought it was ME who hadn’t cut and properly interfaced my projects!!!! :O

What an eye opening column!!! All that shrinkage and bubbling and rippling wasn’t MY fault!!

I am going to test all my interfacings until I can get your interfacing!!

Years ago, I took a zipper pouch class. It was kind of a hot mess, but one thing I did get out of it was to preshrink interfacings and fleece by holding a steam iron over them without actually touching them for a few seconds before adhering them to the fabric. I also cut my pieces a bit larger than the pattern calls for and then I trim them to size after applying interfacing or fleece. This seems obvious, but I have also learned the hard way to READ THE DIRECTIONS that come with the product!

Joan, Thank you for this helpful report. I, too, have been a victim of the dreaded “fabric cellulite”. Very frustrating when you have worked on a pieced project, only to find that when you fuse the fleece it’s ruined.

I will be interested to see what your new search efforts uncover with respect to an acceptable Dreamy Fleece replacement

Hi Susan, My Dreamy Fleece is available at quilt shops and online retailers. Do a Google search for Dreamy Fleece to help find an option. We are currently out of the fusible fleece by the yard, but it is still available in project sized cuts and that item is number SLG1061. Thank you for asking.

So what do you substitute in bags for fusible fleece in the meantime? (I’m having this same problem).